Solvent Recycler RAF 10

- Working tank capacity: 10L

- Working temp. (max in ◦C): 180°C

- Voltage: 230V-50Hz

- Cooling: Aerial

- Efficiency(in liters per 12h): To 20L

- Heating power: 1.6kW

- Thermal oil: 9L

- Weight: 70kg

- Size (in mm): 890x555x1101

- X

- Description

- Technical specification

- Additional equipment

- DTR video

- DTR

- Exploitation materials

- Photos

- For download

X

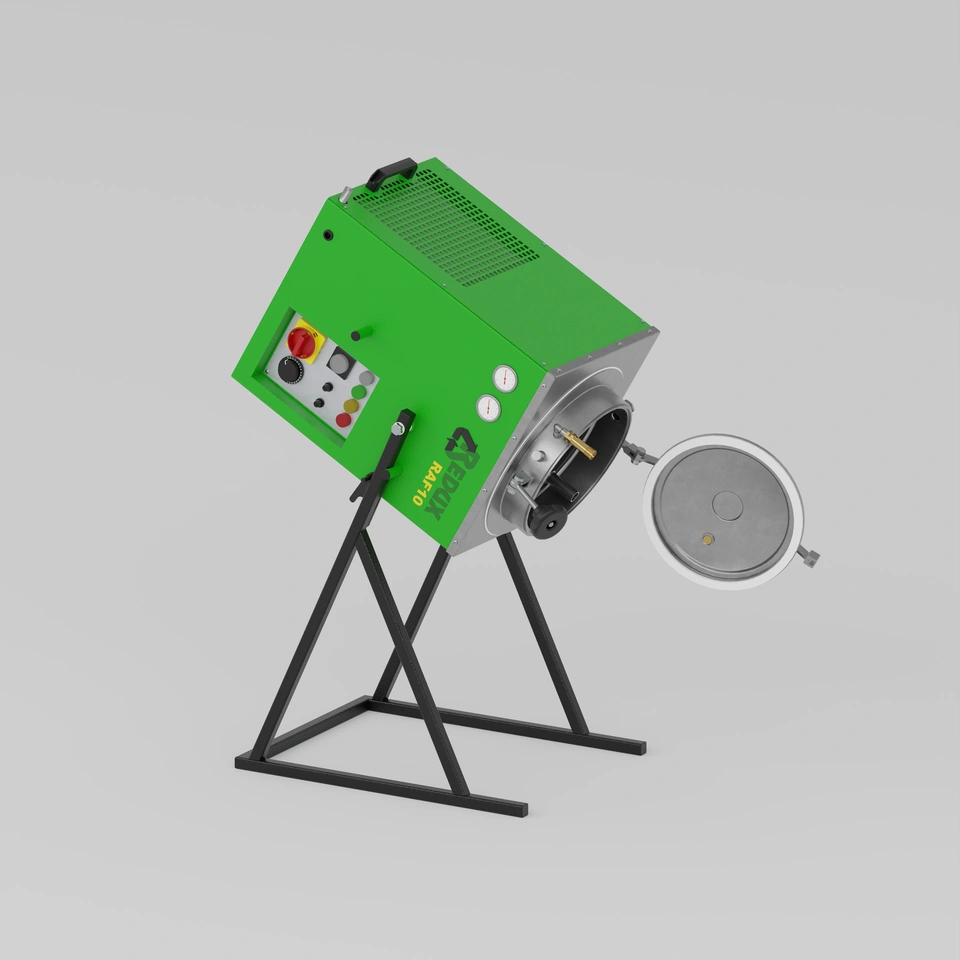

Description

The RAF 10 user solvent distiller has been introduced to meet the needs of having small daily amounts of soil. Fat regenerator such as contaminated solvent in such processes.

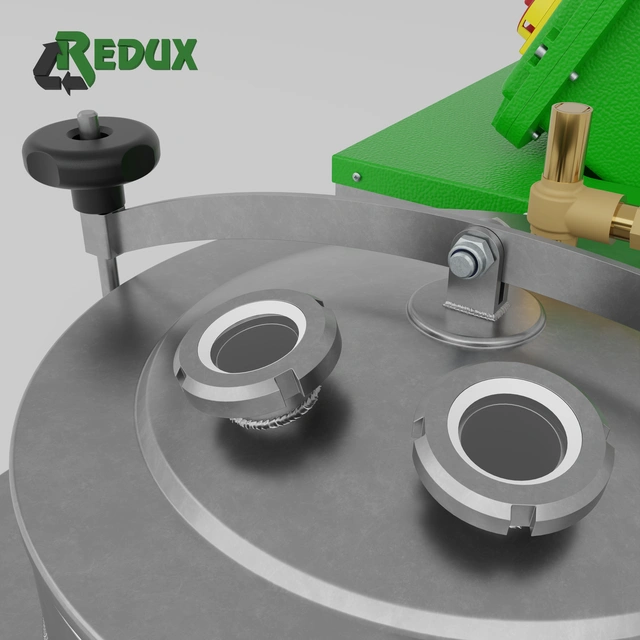

RAF 10 distillers are a construction equipped with a fixed tank with the possibility of its tilt. This function is used to facilitate the purification of the distiller from distillation waste. For even greater ease of use of the device, you can use distillation bags. The use of Redux distillation bags guarantees optimal and safe emptying of still bottoms. These wastes never come into direct contact with the operator, do not contaminate the interior of the distiller vessel, and can be easily disposed of in accordance with the regulations.

The use of RAF 10 distillers is very simple, just put the Redux Bags distillation bag into the tank, place the expansion ring, pour the dirty solvent, set the necessary distillation temperature and start the distiller. After a period of about 30-40 minutes, the solvent will start to evaporate, which, after condensing in the distiller cooler, will „flow” out into the container and can be immediately used again.

Like all products, the RAF 10 series stills are reliable and safe as they are constructed according to the strict European Union standards and have undergone numerous safety tests. The RAF 10 series distillers are equipped with: a vessel – a cooker, a heater and a cover made of INOX 304 stainless steel, and the outer casing is made of welded, powder coated sheet.

RAF 10 distillers are equipped with a copper CU cooler or an INOX acid-proof cooler with air cooling.

In order to facilitate the observation of the distillation process, the RAF 10 distiller is equipped with two temperature indicators. Temperature indicators for distillate and oil.

For the distillation of solvents with a boiling point above 160 ° C, the use of the VACUM SYSTEM REDUX pneumatic vacuum generator is required.

Technical specification

| Technical specification RAF 10 | |

|---|---|

| Working tank capacity | 10L |

| Working temp. (max in ◦C) | 180°C |

| Voltage | 230V-50Hz |

| Cooling | Aerial |

| Efficiency(in liters per 12h) | To 20L |

| Heating power | 1.6kW |

| Thermal oil | 9L |

| Weight | 70kg |

| Size (in mm) | 890x555x1101 |

Additional equipment

Clip

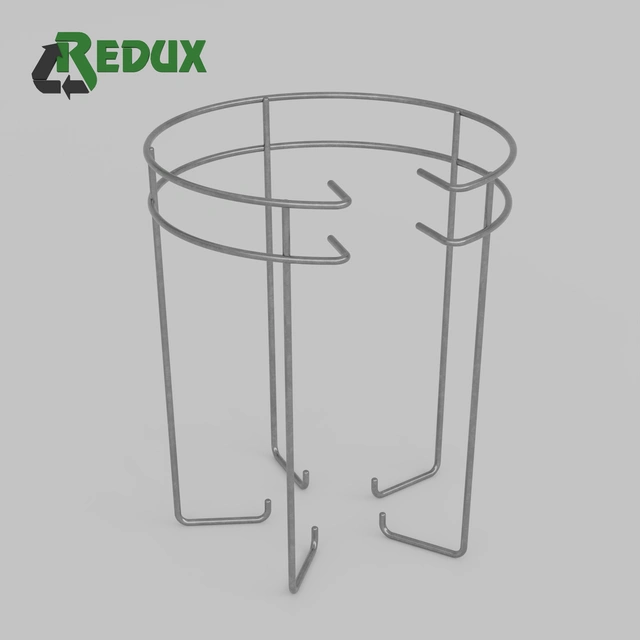

The expanding ring is used to support and correctly position the Redux Bags distillation bag in the distiller tank.

Loading pump

The solvent-resistant pneumatic loading pump is used to fill the tanks of the RAF Series distillers with the liquid intended for distillation.

The sight glasses

The sight glasses are mounted in the lids of the RAF Series distillers to allow observation of the distillation process and to allow the loading of dirty solvent or water using the loading pump in the distillers without the maximum level float.

Pneumatic and electric vacuum

Vacuum device is used for the distillation of high-boiling solvents with a boiling point above 160 ° C. The use of Vacuum lowers the boiling point of the liquid by about 20-25%. We use Vacuum vacuum devices powered by air or electric in our distillers.

DTR video

Exploitation materials

The anti-adhesive

Application:

The anti-adhesive paste is intended for use in solvent distillers. The paste covers the inside of the distiller barrel to prevent paint pigments and other contaminants from sticking to the walls.

The paste also prevents the distillation bag from sticking to the walls of the boiler (digester) in the event of dirty solvent getting outside the bag (e.g. incorrect filling of the above-mentioned boiler).

Types of packaging: 210ml, 1kg, 4.5kg, 10kg

Gasket grease

Application:

Gasket grease is used to prevent the gasket from sticking to the edge of the tank, as well as to improve the sealing between the gasket and the edge of the distiller tank.

Types of packaging: 200ml, 1 kg

Diathermic oil

Application:

We use diathermic oil in solvent distillers as a medium to transfer the heat generated by electric heaters to heat the heating boiler (distiller cooker) which then brings the solvent contained in it to a boil.

Oil in solvent distillers is changed every 1000 hours of device operation or every 12 months, whichever comes first.

Types of packaging: 5L, 10L, 20L

Distillation bags

Application:

REDUX BAGS distiller bags are used in all solvents commonly used in the industry, the boiling point of which does not exceed 200°C. We offer bags with dimensions matching the distillers of all manufacturers.

The bags are used for:

- Elimination of the risk of deposition of distillation waste on the walls of the tank

- Reduce staff costs and time by making it easier to clean the distiller tank

- They minimize the operator’s contact with distillation waste and minimize its impact on the environment

Dimensions:

We offer distiller bags for all types of distillers with a tilting and replaceable tank.